Agility by Design

Maximize your reaction speed to new ideas and unpredictable design changes.

The history-free, geometry-centered modeling approach pioneered by KeyCreator is ideal for projects where quick, un-planned design variations and productive re-use of design data from anywhere are critical. Finish your projects faster by freeing yourself from the constraints and design-lock-in imposed by a parametric CAD database.

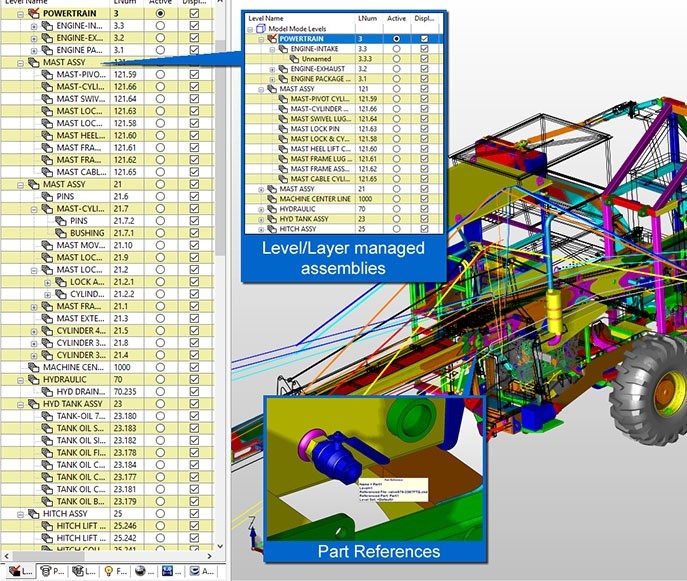

The uncomplicated part, drawing, and file structure of KeyCreator is a significant time-saver for individuals and small teams. Keeping data simple and flexible eliminates time spent managing an overly complex set of separate design files and part relationships. If projects get large, KeyCreator can optimize memory use by moving some sub-assemblies into referenced files.

The comprehensive 3D and 2D tools in KeyCreator have been evolving to meet the needs of manufacturing pros since the ground-breaking first-generation CADKEY program was released 1984.

Design effortlessly with data from any source

Fast, efficient CAD tools with no restrictions

Fix and re-purpose models without rebuilding

Measure and characterize your data

Read and write data in all industry standard formats

Fast NC toolpath generation, no CAM tool necessary

“We are always asked how we can get our designs and tooling done so fast. The answer is KeyCreator.” Kenneth Harris, Manufacturing Engineer, Cardinal Manufacturing

For Cardinal Manufacturing, the key to success lies in their choice of 3D CAD design software.

Louisville, Kentucky is home to three major roll forming companies and competition is fierce. Speed and precision in the design-to-manufacture process is critical for these firms. Roll formers need to quickly quote jobs, create accurate tooling, and produce quality parts in order to keep winning business.

Kenneth Harris of Cardinal Manufacturing is hesitant to share the way KeyCreator has transformed the way his company does business. He says, “I don’t want to tell my competitors about the huge advantage we have over them and shoot myself in the foot.” (If you’re a roll forming company in Louisville that isn’t Cardinal Manufacturing, this is where you stop reading.)

As a roll forming job shop, Cardinal Manufacturing serves customers in industries such as housing, automotive, and even medical implants. Their customers are located throughout the US; they have even done work for companies in Venezuela and China. According to Harris, they are now seeing more on-shoring business. He can think of a dozen big jobs that started in the US, moved to China and are now coming back because of the quality and lead time they can offer.

“The speed at which we can turn around job quotes, including significantly reduced lead times, leaves our competitors in the dust,” Harris says. “KeyCreator allows Cardinal Manufacturing to be more competitive in both design and machining time.”

Before KeyCreator, Cardinal Manufacturing’s lead time for a production roll formed part was as long as 20 weeks. That’s not unusual in the roll form business. Quoted lead times are often quite lengthy to allow for sufficient engineering time as companies need to prepare customer supplied CAD files for production.

Unfortunately, such long lead times created higher costs and left Cardinal Manufacturing vulnerable to their competition. Harris says that when they started using KeyCreator, the lead time went down to 12 weeks “overnight.” That lead time continued to improve and they now experience an average lead time of 4 weeks.

Using KeyCreator means Cardinal Manufacturing can reuse models and NC programming. Designs can be modified to accommodate a variety of changes that speed the design process, without ever having to start a new design. The time from order to first cut is reduced drastically. Harris says, “We are always asked how we can get our designs and tooling done so fast. The answer is KeyCreator.”

Harris shares an example of this speedy turnaround and tells of receiving an order for tooling to produce a roll formed ring (think of a hose clamp). The ring started out as a single profile and single diameter. Over the years, however, that one tooling order resulted in 13 different profiles. Each of these profiles required up to 25 different diameters.

Harris credits KeyCreator for giving Cardinal Manufacturing the speed and ease to make the necessary modifications on this roll formed ring.

“With KeyCreator Direct modeling, we were able to modify the models and produce the complete new designs for the set of tools in less than four hours,” he recalls. “Before KeyCreator those changes/redesigns would have taken two to three weeks. With anyone else, you’d never get that two-week lead time.”

KeyCreator is used for roughly 75% of Cardinal Manufacturing’s designs. Cardinal does have another 2D parametric-based CAD software they use for a small number of designs, but when designs cannot get done correctly or are taking too long, they transition the design over to KeyCreator.

Harris likes the way KeyCreator seems to adapt to each designer’s way of modeling.

“That’s the fundamental reason we like KeyCreator,” he says. “It gives us many ways to do the same function, unlike other software where you have to follow strict guidelines. If you vary from those rules, your design implodes on itself.”

In addition, Harris believes KeyCreator is faster than their 2D program, helping them get 3D geometry to their shop quicker in order to start CAM programming. Now that their customers are used to fast lead times, accurate designs and production parts, Harris says, “If we didn’t have KeyCreator, it would be as if we were designing with a drafting board and T-square.”

Using KeyCreator as a collaboration tool gives Cardinal Manufacturing yet another win against competitors. Customers might provide paper drawings that don’t convey all the necessary design elements required for production. With KeyCreator, Cardinal Manufacturing can work on designs immediately – even in front of customers - or easily review needed changes with customers via a 3D PDF.

“I’m proud to be able to offer such quick project turnaround for our customers,” Harris says. “I’ve seen us get a job quoted and to the shop floor in as little as four hours. There’s nothing like getting started on a project almost immediately. But, what’s even more impressive is completing an accurate customer quote while our prospective customers are still in our conference room. My boss really likes that!"

Outside of his work as an engineer at Cardinal Manufacturing, Kenneth Harris is also owner of Geometric Technologies, a company that provides engineering and programming services to a wide range of customers, many of whom use KeyCreator.

While Harris’s company focuses on tool design, its other specialty is software customization, such as creating KXL macro programs for KeyCreator. These programs can be used to automate tasks and tedious design chores often faced by designers and engineers.

Geometric Technologies has developed several custom programs that “turn an average designer into an expert designer,” according to Harris. “We can do VB/KXL combo programs, as well as write some C++ programs based on what a customer wants.”

A recent project of Geometric Technologies involved a patent-pending design that uses a CMM machine with KeyCreator integration and control. Custom software allows a CMM to draw directly in KeyCreator – not just data points, but lines, arcs, circles and custom shapes drawn by the CMM locations.

Harris is a long-time user of KeyCreator, and also it’s predecessor CADKEY beginning back in 1985. He concludes by saying, “I have tried almost all other CAD programs on the market and always come back to KeyCreator. The software has been the key to saving time and earning our customers’ business.”

KeyCreator really is Harris’s secret weapon. But remember, if you’re talking to other roll form companies in Louisville, Kentucky, mum’s the word on the source of Cardinal Manufacturing’s competitive advantage.

“KeyCreator’s flexibility makes it simple for us to come up with a concept and present it to our customers. We can quickly run the design through several iterations, incorporating the customer’s input, as well as our own ideas.” - Gregory Jensen, President of Jenco Metal Products

Jenco Metal Products of Mt. Prospect, Illinois provides manufacturing solutions such as automation, assembly test and inspection machines, assembly fixtures, components for automation, components for tooling, prototypes, progressive dies, and equipment refurbishment. Many of the products that Jenco produces are one-off, custom specialty projects. Using the latest CAD technologies from Kubotek and cutting-edge manufacturing techniques allows Jenco to continue to become a premier leader in specialty applications.

Gregory Jensen, President of Jenco Metal Products says, “Our company has been using KeyCreator for well over 20 years. Since 1989, we have seen KeyCreator mature into a dynamic engineering design package that provides us with the flexibility to design products quickly in an extremely fast-paced environment.”

Jensen adds, “Kubotek develops their products with the user in mind. In fact, many of the productivity tools that we thought would decrease our engineering and manufacturing times have been incorporated into the product without having asked for them—a true testament to Kubotek’s forward thinking strategy.”

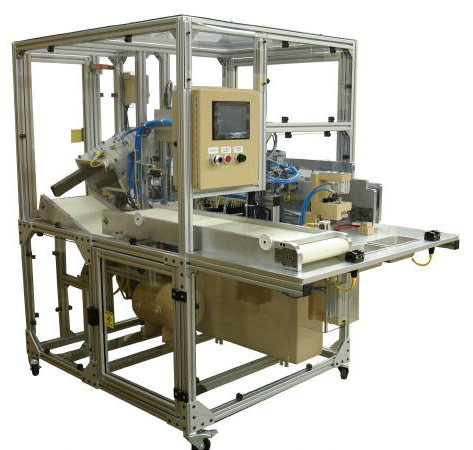

The model shown to the right is an example of a machine designed and built by Jenco. The machine resides in a manufacturing cell and is used for a two-stage assembly process. The first stage is an assembly operation where all parts are inspected and assembled. The parts are then placed on a conveyor where further inspection (and rejection, if required) is performed. Parts that pass this inspection move on and are assembled in a separate tool. The second stage involves placing the assembled parts back into this machine to be leak tested.

Jenco started this project by creating a preliminary rough layout for a system in KeyCreator. KeyCreator allowed them to achieve a concise 3D visual representation of the final product—something that also aided them in the quotation process. Additionally, KeyCreator allowed Jenco to further assess the details of the machine and communicate the details to the customer in real time. “The first time our customer had seen KeyCreator was during our design review,” says Jenson. He adds, “They were very impressed by what they saw. Having the ability to make changes during the conversation was valuable to the customer. We were able to react instantly rather than having to deal with clumsy history trees. One of our customer’s manufacturing engineers asked his engineer ‘Can we do that with our system?’”

Jenson continues, “One of the things that make KeyCreator successful in our organization is the ability of the system to let ideas evolve. All our products are designed as solids. Being able to create a 2D drawing quickly, however, helps us communicate better, especially during initial design meetings. KeyCreator’s flexibility makes it simple for us to come up with a concept and present it to our customers. We can quickly run the design through several iterations, incorporating the customer’s input, as well as our own ideas. We use KeyCreator both as a communication tool and a design tool. This helps us provide the customer with the most refined, well thought-out solution possible in a very short period of time.”

“KeyCreator faithfully allows us to import and immediately work on customer files, not just view and dimension them. Being able to work on any file just as if it had been created in KeyCreator saves me lots of time.” - John Fusi, CEO of JCF Research Associates

Now, imagine the real possibility that you won’t get reimbursed for your time and money. Why? Because you told your client that if you don’t deliver the product on time, they don’t owe you a penny.

That’s exactly what John Fusi, CEO of JCF Research Associates, Inc., did when he began his twelve-year relationship with client Ringling Bros. and Barnum & Bailey Circus. And deliver he did.

Fusi was contacted by the Ringling Bros. and Barnum & Bailey Circus because they needed help with projects that were continually running behind. The first product he helped to produce was a toy to be sold at the circus as a souvenir – a branded handheld globe light that youngsters could illuminate with the press of a button. And it just so happens that toy design is one of Fusi’s sweet spots.

The product included a double-planetary Delrin gear set with a clear bulb and a red LED light that traced lighted Lissajous figures inside a smoked PVC plastic globe. As the lights spin around inside the globe, the wand plays music. The first productions played the Anniversary Waltz, but it changed to other songs over the lifespan of the product. Several characters were mounted on top of the globe, including Mickey Mouse and Minnie Mouse—used for Disney on Ice shows, also run by Ringling Bros.—pink and blue circus elephants, circus clowns, etc.

The very first iteration of the toy included a ball at the base of the wand, a shape that came directly from artwork supplied by Ringling Bros. Fusi, using his keen design sense, pointed out that if they modified the base to create a flat bottom, the wand could stand on its own, making it easy for kids and hawkers to set on a tabletop for demonstration and admiration.

It was a pretty simplistic toy, but the design was a hit. In all, over 3 million units of the toy were sold, making it one of the highest sales volume toys the circus had for a number of years.

Fusi says that the Ringling Bros. and Barnum & Bailey Circus globe light is the project that got him started with CADKEY97, the predecessor to today’s KeyCreator. Fusi hasn’t looked back since. He says of KeyCreator, “I love it.”

One of the things Fusi loves about KeyCreator is that changes, no matter how complex, are typically quite easy. He has firsthand knowledge because changes are a large part of JCF Research Associates’ work; he’s also worked with many parametric CAD programs. Fusi thinks simple changes in parametric CAD programs are okay, but it’s the complex changes that can be “impractical, if not impossible.”

Fusi says, “Some design intent changes are so involved, they force significant alteration to the design’s geometry. In my experience with parametric CAD systems and complex design changes, I find - sadly enough – it’s faster to throw out the old file and start from scratch.”

This doesn’t happen occasionally; it’s actually quite common. According to The 3D Collaboration and Interoperability (February 2013), 43% of CAD users report they recreated foreign design data rather than fixing it. For a firm that routinely needs to deal with extensive design changes during development cycles, like JCF Research Associates, using KeyCreator totally eliminates the need to recreate files.

Much of JCF Research Associates’ work involves creating manufacturing ready 3D CAD for clients. They often receive project files in various CAD and non-CAD vector formats, including unrefined early stage 3D CAD from different CAD platforms like Pro/ENGINEER, SolidWorks, Autodesk products, CATIA, etc. Fusi uses the customer supplied files to make modifications and/or additions as they find necessary, until a design package is complete and ready to send to a manufacturer.

Client files often need things like draft or clearance added to make them truly manufacturable. And of course, Fusi also takes into consideration what types of tolerances can be held in machines and incorporates those into client designs.

“KeyCreator faithfully allows us import and immediately work on customer files, not just view and dimension them. Being able to work on any file just as if it had been created in KeyCreator, saves me lots of time. I can safely say that KeyCreator saves me time every time I use it, and time is money.”

Fusi concludes, “KeyCreator is not only the best CAD software for our needs, it is the only choice that gives us the flexibility we need on a daily basis. There are always iterations of designs. And if any other business has needs like ours, KeyCreator is not only my strongest recommendation, it is my only recommendation.”