Rhino-NC is a 3D CAM software for CNC machines and robot programming. This solution is really easy and quick to learn and works on any kind of machine: high speed, multi-function, old CNC. Rhino-NC is extremely flexible and really powerful and ensures effective programming and performance. Rhino-NC 's can be applied in the following fields: mechanical, toolmaking, mould industry, modelling and prototyping, shipyards, petrochemical industries, etc.

CURVES, SURFACES AND SOLIDS

This version of Rhino-NC allows to manage the machining either on curves, surfaces and solids. The software comes complete with several libraries like "Tools Archive" and "Machines Archive" which can be updated and customized by the user. The graphic interface is based on wizard with text fields and related images. It allows a simple and intuitive input of the different parameters to control each strategy, with graphic dynamic help, varying the displayed images on the basis of selected parameter.

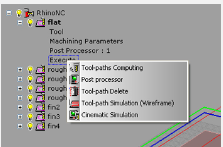

MODULES: AN EASY CONFIGURATION

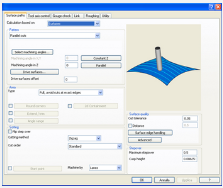

The 2,5 axis module is used for curves, 2D and 3D profiles open and closed) machining. The strategies included are: flattening, engraving, contouring and pocketing. The machinings can be optimized as: sequence type, approach and detach, with or without tool radious correction from PC or CNC. The machining can be limited by box or profiles. RhinoNC includes an archive of geometric and technological rules of any kind of simple of complex drill. With these rules, RhinoNC automatically generates all the drill cycles, also in 3D environment. Tools to be used are automatically picked up from the tool archive or included if missing. The hole types managed are: drilling, boring, threading, flaring, reaming, etc. or composed like, deep hole with boring and chafer or drilling, boring, chamfer and threading. In the machining three you will see the development of every single machining taht can be modified. 3 axis module is used for 3D model machining. It includes all strategies, as roughing, rest material, finishing. The are many working technologies that let the users to nachine every kind of object. A special care has been dedicated to the morfological pocketing optimization and many solutions for high speed machining has been added.

5 AXIS

The advanced multi-axis machining module, provides new machining strategies for an advanced use of the multi-axis technology (4 o 5), thanks to the increased accuracy and fluency of the toolpath generation it's possible to reduce machining times.

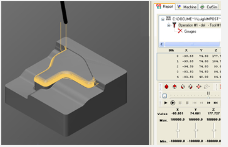

KINEMATIC SIMULATOR

The generated toolpath can be simulated inside Rhinoceros using the cinematic simulation with full collision detection. The cinematic simulation considers the upload of the full CNC, of the equipment and the piece to be machined. This offers the ability to create toolpaths avoiding any risk of wrong positioning and to be ready for the production. Simple management of multi-axis post-processing once the CNC cinematic has been set up. The output file for the machine tools is managed by postprocessors fully user-definable by means of a simple text editor.

POSTPROCESSOR

Reliable Post Processors for most of the machines are available. Additional post processors are always under development due to new customer requirements.